Here, we aim to identify the industries that we think can profit the most from additive manufacturing, given the abundance of businesses employing professional 3D printers in their production processes. It’s simple to see how and why professional 3D printers are revolutionizing production by taking a look at these sectors. Learn about the top three industries that use SLS (selective laser sintering) printing.

Aerospace Industry

Some of the highest criteria for component performance exist in the aircraft sector. This is because the parts can jeopardize the safety of pilots and passengers if they have even slight issues. Aerospace components made out of 3D printing filaments need to be as strong as possible while withstanding high temperatures, harsh chemicals, and frequent loads. Failure is simply not an option when an airplane is transporting people or goods since single-part failures frequently lead to whole-system breakdowns. Aerospace engineers have turned to SLS printing inspection tooling to cut costs for low-volume components since part quality is essential for aircraft.

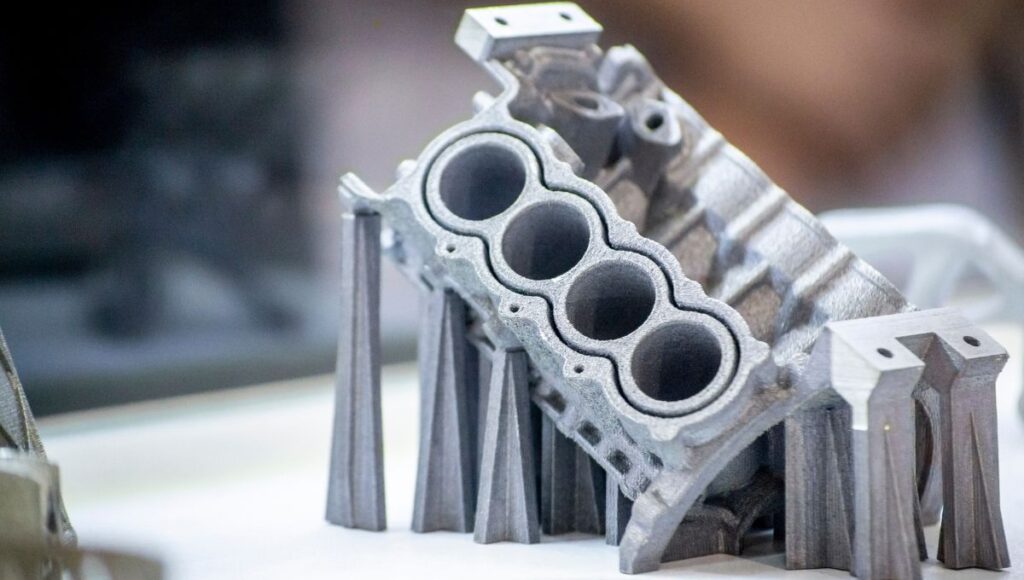

Automotive Industry

With prominent corporations like Audi adopting SLS printers, the automobile sector has been leading the way in manufacturing processes. Everyone from race car teams to the original equipment manufacturers (OEMs) are using these specialized parts printers, not only the Audis of the globe. The SLS printing sector for car manufacturers initially centered on creating the fixtures and tools that support the production process. This continues today. Fixtures, cradles, and prototypes are the most often items that the car industry prints. They require the rigidity, strength, and durability that SLS printing can provide.

Robotics Industry

As luck would have it, robotics is one of the top three industries that use SLS printing to meet its structural goals. These elements make effective robotics parts that combine well with SLS printing capabilities since it increases customizability and reduces weight. Grippers and sensor mounts are pricy to produce and need bespoke designs for various applications. Robotics experts employ SLS printers for end-of-arm tooling and end-use parts, ranging from gripper fingers to full robot components. They do this to lower the total weight of the product and enable the tools to move more quickly and carry larger loads. SLS printing industry innovations enable robotics businesses to design and build light, sophisticated parts, such as end-of-arm tooling, for a fraction of the cost. It’s clear that this is advantageous as opposed to spending lots of money on a non-customized design.

We hope our article has given you insight into how some important industries use SLS printing. It truly is a versatile and innovative technology. Be sure to take note and use its benefits to your advantage. With SLS printing, you can make marked improvements in your own manufacturing process.