It’s a critical ingredient in many of our favorite dishes, it’s on our tables, and it’s all over the roads (and the vehicles that use them) in the winter. But did you ever wonder where salt comes from and how it’s processed? I looked into three methods of salt production, and along the way, I discovered something important about a common expression with origins in the disturbing history of salt mines.

The phrase “back to the salt mines,” which many people use in an offhanded way to refer to being called back into the office, has an alarming history: it likely originated with the Russian forced labor practice of sending prisoners to work in salt mines in both the imperial and communist eras! And historically, forced labor had been used to extract salt from the earth. Salt mining subjected prisoners and enslaved people to all the dangers of mining, including tunnel collapses and suffocation, as well as severe dehydration from constant salt exposure.

Fortunately, the top three methods of salt production are now better regulated in many countries because of the advocacy of labor unions and legal requirements put in place to protect workers. Learn more about modern methods of road and table salt production.

Solar Evaporation Method

The evaporation method extracts salt from seawater or other natural brine sources through the power of the sun and the wind. Salt producers construct flats and ponds in warm, arid climates with abundant sunlight and very little rain. The sun’s heat evaporates the water, leaving a concentrated salt solution and eventually forming raw salt crystals which are then harvested for further processing

Rock Salt Mining

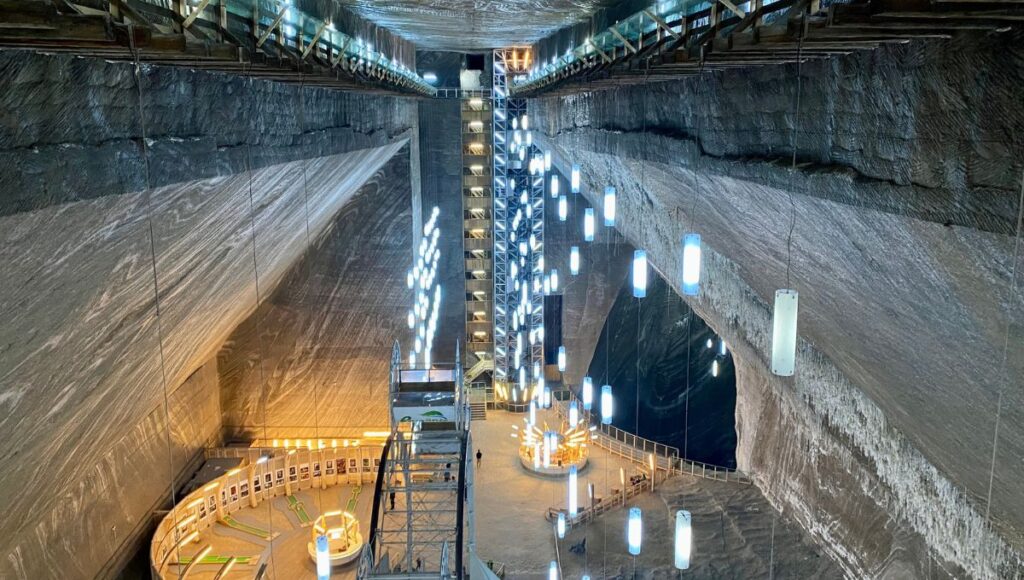

In this method, salt deposits are extracted from underground mines, often carved into mountains or other mineral-rich geological formations. The process includes using rock drilling equipment to bore deep into the deposit, blasting to dislodge the salt, and transporting the raw salt to the surface for processing.

While some rock salt mines still use traditional manual labor, advancements in technology have made this method less labor-intensive in recent years.

Solution Mining

This technique involves pumping water into underground salt deposits to dissolve the salt. The resulting saltwater solution (brine) is then pumped back to the surface, where the water is evaporated using various methods including vacuum evaporation, which boils all the water away leaving pure salt crystals.

Solution mining can produce a diverse range of salt types, making it a versatile method that’s employed worldwide.

Processing Salt for Different Uses

Regardless of the harvesting method, salt usually undergoes further processing before it reaches our tables or roads. The processing may include washing, centrifuging, and further drying or filtration to remove impurities. Processing may also involve grinding the salt crystals to a specific size and texture for table or industrial use, adding anti-caking agents or iodine to table salt, or processing salt with other chemicals for de-icing purposes.

Understanding three methods of salt production provides insight into our culinary and industrial world. After looking around the internet for information on salt, I’ve come to appreciate the complexity of salt production. While appreciating salt’s critical role in so much of my cooking, I’ve also learned to treat the phrase “back to the salt mines” as a reminder of harsh and inhumane salt mining practices of the past.